Automatic Double Heads Sleeve Labeling Machine

Product Description

Automatic Double Heads Sleeve Labeling Machine

Products Introduction

Application

The machine is designed to achieve the Rationalization of production target. Labeling process automation, simple operation,The production speed is quick, labeling position, beautiful, neat, This equipment isMainly used in food, beverage, pharmaceutical, cosmetic, chemical industry.

Working Mechanism:

Feed the packages onto the conveyor, then packages will be separated in certain

Distance gap by the division device on the conveyor. The movement and outing of label

Is controlled by photo sensor. Label will be nicely stick on the packages after rolling

And pressing device. After labeling, packages are moved into next step by conveyor.

Double Head Shrink Sleeve Labeling Machine introduction:

1. Driving unit:Synchronized transmission,any change of transmission belt will be finished quickly.Compared to the type of traditional multilayer whose change and maintain need more than six hours,its maintenance is easy and maintain is simple,so it doesn`t influence production

2. Cutting head unit:The new style cutting knife driven by servo motor,with high speed,more stable and precise,shrink perfectively. Synchronous locating device enables the tolerable error to ±1mm.Unit cutter head plane design in China which fit to the container of 30mm-130mm.you never need to change or debug it.It also has unique light touch human-machine screen,that meansauto search original location as well as safety and convenience which is ahead of other congener products.

3. Label feeding unit:It adopts single material shelf which enable the change of label more convenient and fast. It adopts transducer with mechanical buffer device which enables the label feeding stable and fluent and when there is no material, it will stop automatically and give alarm light and also display on the touch screen.

4. Clean down unit:Adopted with motor coordinating with double circular arc synchronous belt makes clean down plastic core-rubber-tires synchronously and ensures the label casting stably

5. Bottle carrying unit:Adopted with mechanical transmission to drive the positioning belt on both sides.While changing the whole bottle carrying unit, the down and up, width are all controlled by one hand-wheel aiming to synchronously and swiftly adjust.

6. Clean-down unit: Adopted with electric to adjust more conveniently and fast

Double Head Shrink Sleeve labeling machine Parameter:

| Model | DSL-250 |

| Capacity | ≥8000BPH(Calculation of standard length≤100mm)

|

| FPY | ≥99.9% |

| Whole line productive efficiency | ≥95%(Calculation of 24 hours) |

| Applicable diameter of bottle | 28mm~ 125mm |

| Applicable length of label | 30mm~250mm |

| Applicable thickness of label | 0.027mm~0.13mm |

| Label material | PVC,PET,OPS |

| Label transparent space | ≥5mm |

| Volume label inside diameter | ≥4"(101.6mm) |

| Volume label outside diameter | ≤500mm |

| voltage | AC380V,50/60HZ, three phase |

| label sleeving machine output | 1.5KW-2KW |

| Shrink tunnel output | A:0.37KW(steam shrink tunnel)/B:18KW(electrical shrink tunnel) |

| Steam pressure | 1-8Kg/cm2 |

| Steam air consumption | <25Kg/hour |

| Dimension of the machine | Host label sleeving machine:L2000*W850*H2000 Steam shrink tunnel: L1500mm×W500mm×H1500mm |

| Weight | 400 kg |

Packaging and Shipping

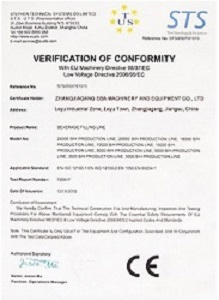

Certificate

FAQ

Q: How about the spare parts?

A: We will send one year enough easy broken spare parts together with the machines, shipping together. During the warranty time, we will supply the spare parts with our cost including the delivery fees.

Q: How long time for installation?

A: According your machines order, we will send one or two engineers to your plant, it will take about 10 days to 25 days.

Q: How to install my machines when it arrives? How much the cost?

A: We will send our engineers to your factory to install the machines and train your staff how to operate the machines. Customer pay air tickets go and back accommodation and USD80/day/person.

Q: When can I get my machine after I paid?

A: Normally production time is around 30-60days, the exactly depend on what kind of machine you order. The shipping time is based on your destination port.

Q: What`s your guarantee or warranty of the quality if buy your machines?

A: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q: Are you a trading company or a manufacturer?

A:We are an original equipment manufacturer so that we can provide you high quality machines in reasonable price. Welcome to visit us.

Product Categories : Labeling Machine > Double Heads Sleeve Labeling Machine