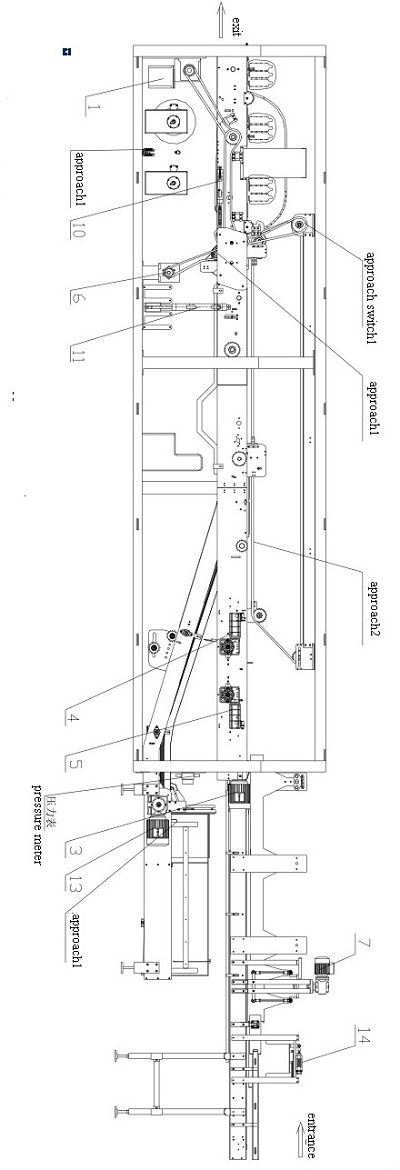

Bottle Hot Shrink Film Wrapping Machine Half Tray

Product Description

Bottle Hot Shrink Film Wrapping Machine With Half Tray

Technical parameter:

● Power supply. Total power: AC480v+10%/50Hz,7.5KW (three-phase)

● External gas source: 4-6kgf/cm2

● main motor: 380V 3300W

● Bottle separate electricity motor: 380V 820W*2

● Exit belt motor: 380V 750W

●Film cutting electricity motor: 380V 820W

● Film feeding electricity motor: servo 1480W

● Bottle entry plate chain electricity motor: 380V 1100W

●Whole bottle motor:380V 250W

●Machine size (L*W*H):12069*1670*2480mm

(Can make according to special requirement).

●Package piece speed: ≦45package /minute

●Package product size: can according to client special requirement.

●Working platform heightL:1150+50mm(can making according to special requirement).

●Conveyor belt: shanghai

●Usage film type: PE film

●PE film width: according to client requirement. film thickness:0.07mm-0.08mm;

●Film shrinkage ratio: length wise direction 70-80%, cross wise 20-30%.

●Circumstance condition: humidity≦98%, temperature:20-40℃.

●Noise: at working circumstance, noise ≦75DB.

●Whole machine all set safe protection device

●While package type not change, just need to change bottle height and bottle neck diameter, just need 20 minute; while not change bottle neck diameter and bottle height, just change package specification, not more than 15 minute.

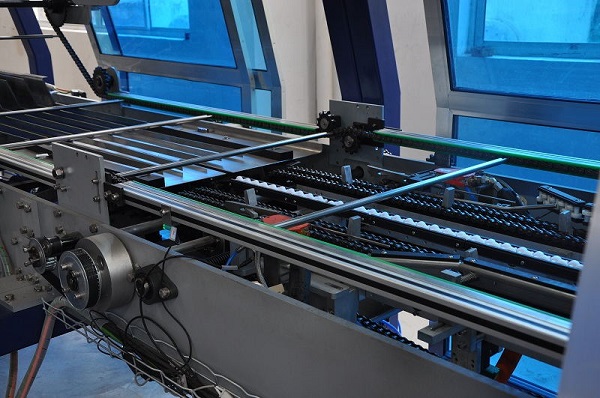

● Bottle entry belt drive by frequency motor, adopt to plastic chain net belt conveyor; in addition, match one set of frequency transducer controlling and facility connecting conveyor chain, ensure bottle smoothly enter into each channel tunnel; according to product package type, via vibrate parse device divide product; each channel bottle arrange and number control by conveyor belt top sensor; can control entrance bottle stream pressure according to entrance bottles streams; bottle entrance place set inspection device of bottle full and lacking situation, can let bottle efficiency separation.

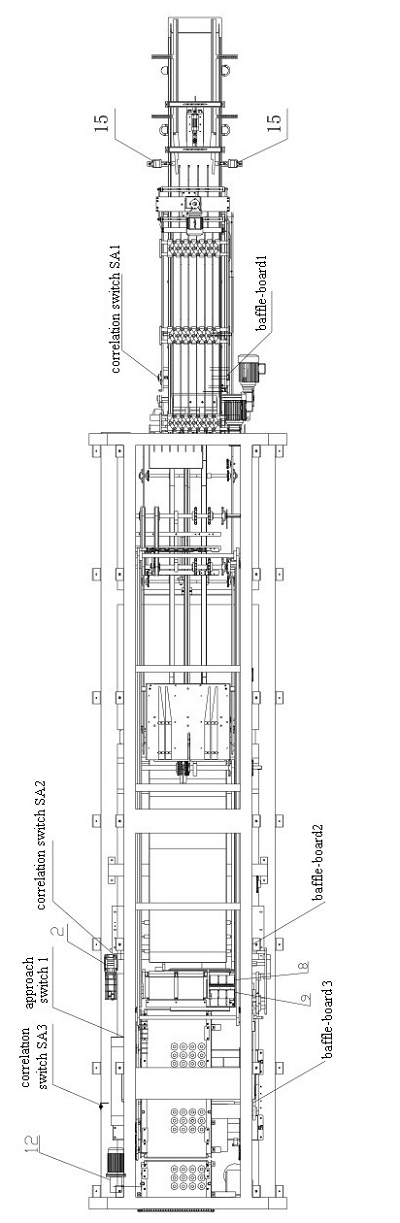

● Bottle separate and group: two group shifting fork that drive by servo motor, group bottle as package required number, adopt to linear bottle separate, control by servo motor, accuracy locate, easy to debug, very reliable.

● Bottle hander film wrapping: via bottle handing pole control each group bottle movement distance, let it synchronization with film lifting pole, and let bottle push to film wrapping section belt; film lifting pole and film lifting device match torsion limit stopper, while bottle drop or bottle block, limit stopper movement let machine auto stop, after failure solve, then turn limit stopper hand wheel reset.

● Mechanism rotation: the machine rotation drove by servo motor, adopt to synchronous belt and chain rotation assembly method, ensure rotation harmony, the place that adopt to chain ration all add protection covet and lubricate device, ensure worker safe and circumstance clean.

● Have the function: while lack bottle, the machine will alarm, no bottle no film feeding function

● Controlling system: adopt to PLC and touch screen controlling, have manual. Auto move method, touch screen have full machine manipulation function, can display instant and accumulated package quantity, and enable can print with the connected printer. Setting procedure is more quick and precise; controlling panel adopt to electronics touch and control button controlling, can directly input and revise package type parameter, also can save different package specification parameter; timely supervise facility operation whole process. All the working procedure all have sensor checker, have ego diagnose function, if have any breakdown, facility will auto stop, alarm light blink, display breakdown type indication on the touch screen; common type reducer motor matching frequency transducer, whole machine limitless speed adjust, move transmission is very steadily; can as above situation change, auto control machine movement speed.

● Mechanism character: mechanism spare parts adopt to stainless steel, chroming steel and strong anti-corrode character aluminum alloy ect material; surface good quality spray printing, whole machine have strong anti-rust character.

● The facility accord with safe manipulation and safe operation related criterion and standard. All the lubricate part connect central place, for convenient to handle, lubricate part all ensure have no pollute on the product.

● Performance character: high automatic degree, the machine choose PLC programmable control, electricity part all adopt to import reliable pneumatic device and super electricity controlling technology, have steadily character, easy to handle, low failure, high automatic degree ect advantage; easy to handle; the machine belong to full auto production, and can limitless speed adjust and whole line synchronization operation.

● Electricity collocation: Siemens PLC controller, Schneider contactor, FOTEK sensor switch, FESTOR pneumatic element, SIMENS servo motor, SEW electricity, SIMENS touch screen manipulation.; sensor switch, approach switch adopt to P+F product; low pressure pneumatic element adopt to France Schneider product, other element all adopt to famous brand.

●Working flow: open power supply switch, cross film, choose manual film cutting, after one time film cutting success, then choose auto, machine start to operate. Product via bottle split flow facture, guiding fracture, bottle separate fracture, bottle handing film lifting up fracture, film wrapping fracture, at last via shrink tunnel, then finish whole film wrapping package working.

related product: Film Shrink Wrapping Machine,Hot Shrink Film Wrapping Machine,Small Shrink Wrapping Machine,Film Heat Shrink Wrapping Machine,Auto Shrink Packing Machine

Picture

Packaging and Shipping

Certificate

FAQ

Q: How about the spare parts?

A: We will send one year enough easy broken spare parts together with the machines, shipping together. During the warranty time, we will supply the spare parts with our cost including the delivery fees.

Q: How long time for installation?

A: According your machines order, we will send one or two engineers to your plant, it will take about 10 days to 25 days.

Q: How to install my machines when it arrives? How much the cost?

A: We will send our engineers to your factory to install the machines and train your staff how to operate the machines. Customer pay air tickets go and back accommodation and USD80/day/person.

Q: When can I get my machine after I paid?

A: Normally production time is around 30-60days, the exactly depend on what kind of machine you order. The shipping time is based on your destination port.

Q: What`s your guarantee or warranty of the quality if buy your machines?

A: We offer you high quality machines with 1 year guarantee and supply life-long technical support.

Q: Are you a trading company or a manufacturer?

A:We are an original equipment manufacturer so that we can provide you high quality machines in reasonable price. Welcome to visit us.

Product Categories : Packing Machine > Bottle Packing Machine